Optimizing Efficiency while Meeting Refrigerant Demands

Figuring out how to meet the HVAC&R industry’s evolving refrigerant regulations and safety codes while developing the world’s first oil-free, magnetic bearing centrifugal compressor that can be used with either HFO-1234ze or R-515B is no small feat.

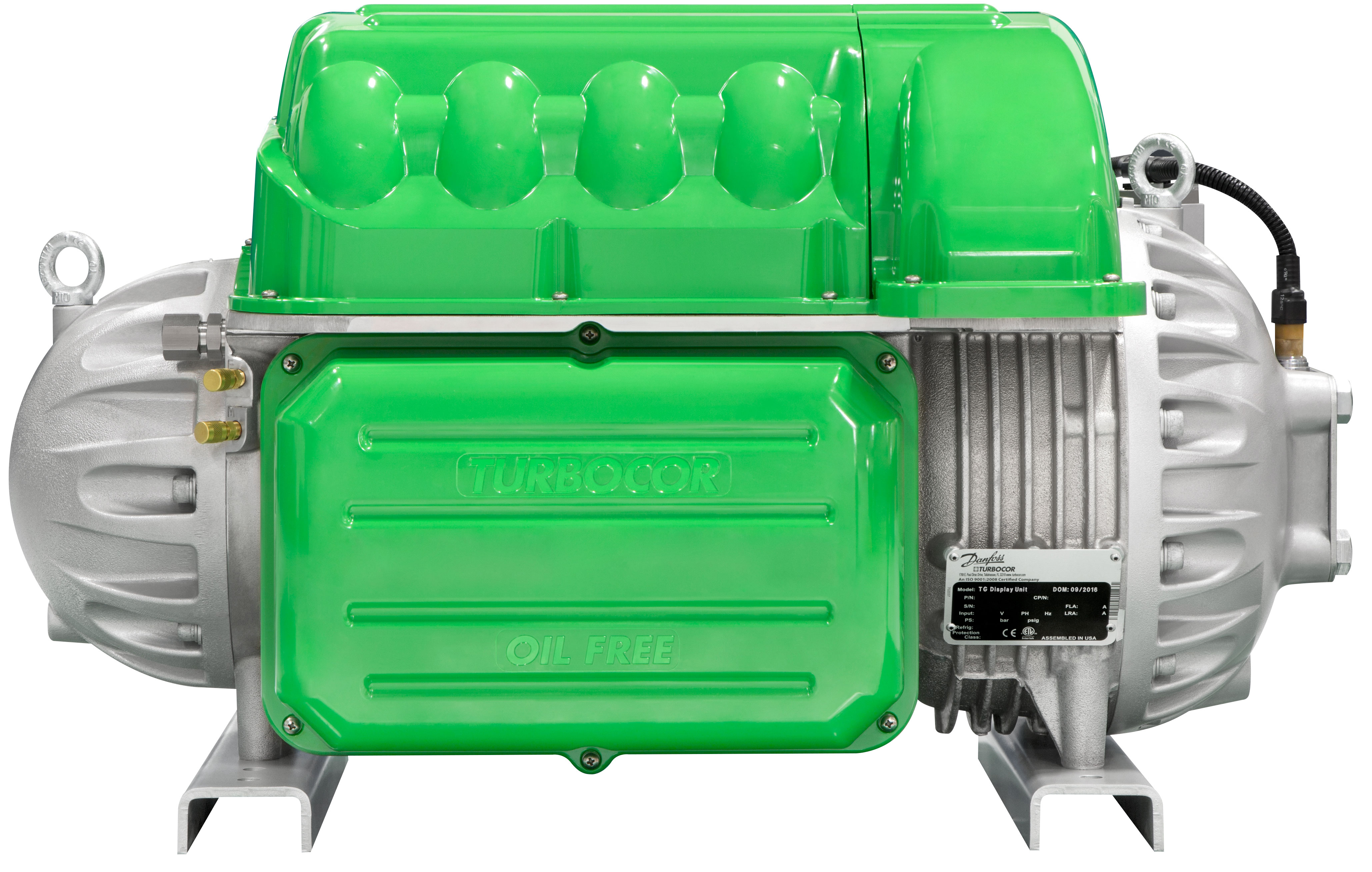

The Danfoss (Booth 1501) Turbocor® TG490 centrifugal compressor—the winner of the 2020 AHR Expo Innovation Awards green building category—allows users to operate a reliable, high-efficiency oil-free compressor with a refrigerant option that offers both low-global warming potential (GWP) and an ASHRAE A1 safety classification for compliance with applicable refrigerant regulations and safety codes.

“The Danfoss Turbocor TG490 compressor is the world’s first oil-free, variable speed, magnetic bearing centrifugal compressor that can be used with either HFO-1234ze or R-515B,” said Eddie Rodriguez, strategic marketing manager for Danfoss Turbocor Compressors. “R-515B has a GWP of 299 and an ASHRAE A1 safety classification—allowing users to be compliant with applicable refrigerant regulations and safety codes.”

HFO-1234ze refrigerant, which has a GWP of less than one, can help the industry reduce harmful emissions, which will help minimize the environmental impact of using HVAC equipment, said Rodriguez.

With a nominal 125-ton capacity, the compressor can be used in air- or water-cooled chillers to provide chilled water for comfort cooling or process applications.

Behind the Winning Product

Using oil-free, magnetic bearing technology and an integrated variable speed drive, the Danfoss Turbocor TG490 has a less complex and more reliable chiller design.

“At the heart of this technology are the magnetic bearings, which are used to create a magnetic field that allows the compressor motor shaft to levitate and avoid metal-to-metal contact,” said Rodriguez. “This eliminates the need for oil as a lubricant and thus the entire oil management system, including oil pumps, heaters, sumps and separators, as well as the cost of installing these components.”

An international group of aerodynamic and mechatronics engineers designed the compressor, which is manufactured at the Danfoss Turbocor Compressors facility in Tallahassee, Fla.—located about 250 miles northeast of Orlando, the location of the 2020 AHR Expo.

“The team was dedicated to maximizing the efficiency of this new compressor and utilized several new modeling techniques that were developed in-house to create the initial compressor design while minimizing the number of iterations tested,” said Rodriguez.

The team worked with select customers to understand specific operating conditions to help the compressor achieve optimal performance at unloading conditions. This was done to achieve maximum ECODesign SEER ratings and IPLV ratings at AHRI conditions, he said.

During the product development phase, the team encountered a few challenges, said Rodriquez. The Danfoss Turbocor Compressors facility was going through several changes including a new lab expansion, and Danfoss had to commission a new test chiller, which was required for this development effort. The team also faced challenges as the new R-515B refrigerant was still in development.

The product expands Danfoss’ Turbocor TG compressor series, which was the first line of oil-free, magnetic bearing centrifugal compressors to use HFO-1234ze.

For additional coverage of AHR Expo, visit ASHRAE Journal’s AHR Today web page.