Heat Exchanger Improves Two-Circuit HVAC Systems

A twist on an existing technology could help the U.S. HVAC market meet expected increased efficiency requirements.

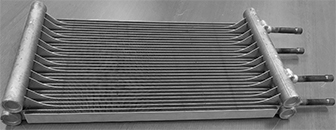

Danfoss’ (Booth 1501) interlaced microchannel heat exchanger (iMCHE) integrates multiple circuits into a single coil with shared air heat transfer area, controlling each one independently by a multi-circuits system.

As the U.S. HVAC market is faced with significant increases in efficiency requirements starting in 2023, the product can exceed those targets thanks to improved operation and performance, said Jeff Tucker, global head of heat exchanger business development for Danfoss.

“Danfoss is the leading supplier of HVAC solutions to support customer redesign projects to meet these new standards,” he said.

The product’s primary focus is for two-circuit rooftop unit (RTU) applications where system suppliers want to improve overall product performance to meet next-generation efficiency requirements, said Tucker. The iMCHE’s target products range from 72,000 to 600,000 BTUh and can be provided for both outdoor condenser and indoor evaporator applications.

“Higher system efficiencies typically require improved compression, air movement and heat transfer technologies. The most common and easiest method to increase heat transfer is to increase overall heat exchanger surface area,” said Tucker. “This is undesirable as size increased heat exchangers require increased cost and increased system product size. Selecting iMCHE allows for achievement of efficiency targets without changes to product size and offers best applied system cost.”

How Does It Work?

The iMCHE is a next-generation solution to improve the operation and performance of two-circuit HVAC systems, he said. Interlaced heat exchangers have been available for years and use round tube plate fin designs. Due to an industry technology shift, a Microchannel (MCHE) technology solution was required to displace previous technology.

“The Danfoss iMCHE allows for two independent refrigerant circuits to utilize a shared finned face area resulting in improved heat transfer performance during part load operation. The two refrigerant circuits can be equal in capacity or can be different capacities,” said Tucker, adding the product can be configured to optimize any circuit split combination.

The iMCHE can be provided as a one-pass slab design or as a “folded” design utilized in evaporator counter-flow applications, he said.

The Danfoss iMCHE integrates two independent refrigerant circuits into a single heat exchanger, said Tucker. The tube forming process allows for dual manifolds to be combined into a single finned area.

“The result is overall higher system performance with no increase in heat exchanger size and no need to increase overall product size,” he said.

The design allows for multiple heat exchanger configurations that easily adapt to the customers’ needs, according to Tucker. Different configurations can be used in both equal or unequal refrigerant circuit design:

- Outdoor condenser applications using a flat slab design

- Outdoor condenser applications requiring a corner-radius formed design

- Indoor evaporator applications using a single-pass slab design

- Indoor evaporator applications using a “folded” counter-flow design

“All evaporator design utilizes integrated refrigerant distribution technology to allow for simple, clean installation into the final system product,” Tucker said. “The overall result is a cost effective, easy to apply, system performance enhancing technology to meet future efficiency requirements.”

For additional coverage of AHR Expo, visit ASHRAE Journal’s AHR Today web page.