©2020 This excerpt taken from the article of the same name which appeared in ASHRAE Journal, vol. 62, no. 5, May 2020.

About the Author

Benjamin D. Hobbs is a mechanical engineer at CMTA, Inc., Lexington, Ky.

The new Frederick Douglass High School is a two-story, 287,125 ft2 (26 675 m2) facility serving 1,800 students and 150 staff in the Fayette County Public School District in Lexington, Kentucky. The facility added the capacity required in the rapidly growing school district with the intent of being the district’s first net zero energy–ready high school. It also is home to the Carter G. Woodson Academy, a 6th–12th grade academy focused on high-potential minority males in the district.

Energy Efficiency

The high school was designed through parametric energy analysis based on accumulated metered data and knowledge of ANSI/ASHRAE/IES Standard 90.1 Energy Standard for Buildings Except Low-Rise Residential Buildings, design parameters to select highly efficient systems and equipment.

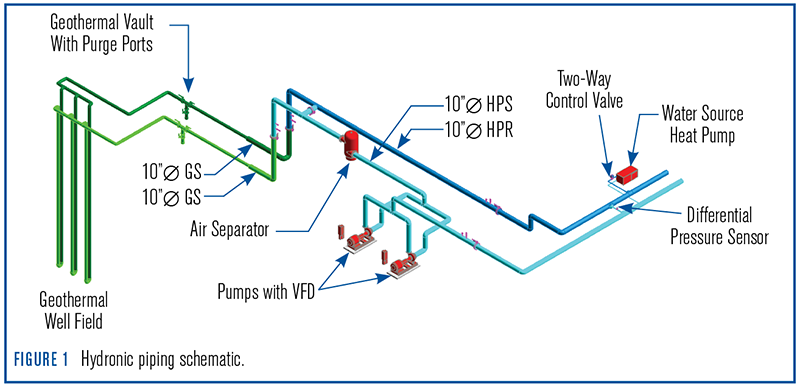

A geothermal field under the parking lot consists of 452, 300 ft (91 m) deep bores on 20 ft (6 m) centers and serves as the building’s heat source/sink for the heat pump system. The earth either absorbs heat from or rejects heat to the system’s building loop piping as required to keep the loop within design parameters, negating the need for a boiler or cooling tower. Most of the system’s heat pumps are two-speed so that the units can cycle to low speed at part-load condition. All of the heat pumps have an EER over 21. The two-way valve on each heat pump closes when the compressor is off to minimize pumping energy.

A single centralized geothermal pump with a 100% backup pump circulates the geothermal water through the field and building. Three pressure sensors located in remote parts of the piping circuit measure the differential pressure between the heat pump supply and the heat pump return to regulate the variable frequency drive on the main centralized pump (Figure 1).

High-volume low-velocity fans were provided to supplement air circulation in the two-story cafeteria, gymnasium, and auxiliary gymnasium. These fans draw only 5 A at 120 V, and the increased air velocity allows for a higher space temperature setpoint during the warm seasons, thus saving compressor cooling energy. The fans alone have proven to keep the gymnasium and auxiliary gymnasium sufficiently cool during after-school and weekend activities, saving additional energy.

With the use of efficient systems and equipment, the school currently operates at an energy use intensity (EUI) of 18.3 kBtu/ft2 (207.8 MJ/m2). It has achieved a 100 Energy Star rating, making it the first perfect score Energy Star high school in Kentucky and the most energy-efficient high school in the state. This outcome has exceeded the design team’s expectations and projected energy performance compared not only to the district’s previously best-performing high school but also to the average K–12 school and the average Energy Star high school score of 75. According to Energy Star, the average site EUI for K–12 schools is 48.5 kBtu/ft2 (550.8 MJ/m2), so this building represents a 60% savings over the average.

Indoor Air Quality

The building was designed around a demand-control ventilation system. This system utilizes individual CO2 sensors in each occupied space that direct the outside air supply based on the location of the occupants. Each space has a variable air volume (VAV) box that modulates to maintain a room CO2 level of 700 ppm above the ambient CO2 level. This approach allowed the outside air unit to be right-sized for the number of occupants and square footage of the building and to deliver fresh air directly where it is required, while still meeting the requirements of ANSI/ASHRAE Standard 62.1-2010, Ventilation and Acceptable Indoor Air Quality. A single 30,000 cfm (14 158 L/s) VAV air-handling unit provides clean, filtered, neutral room temperature outside air to every occupied space in the building. The building relief air and exhaust are drawn back to this unit, and the outgoing airstream’s sensible and latent energy is reclaimed with a desiccant energy recovery wheel.

Read the Full Article

ASHRAE Members have free access to the full-text PDF of this article as well as the complete ASHRAE Journal archives back to 1997 in the Free Member Access Area.

Non-members can purchase features from the ASHRAE Bookstore. Or, Join ASHRAE!

Return to Featured Article Excerpts

Return to ASHRAE Journal Featured Article Excerpts