©2025 This excerpt taken from the article of the same name which appeared in ASHRAE Journal, vol. 67, No. 7, July 2025.

Chemistry, Regulatory, & Performance Aspects Of Antimicrobials For HVAC&R Components

By Phil Coffman

Phil Coffman, Ph.D., is the director of quality and regulatory affairs at Decon7 Systems, Inc. in Coppell, Texas.

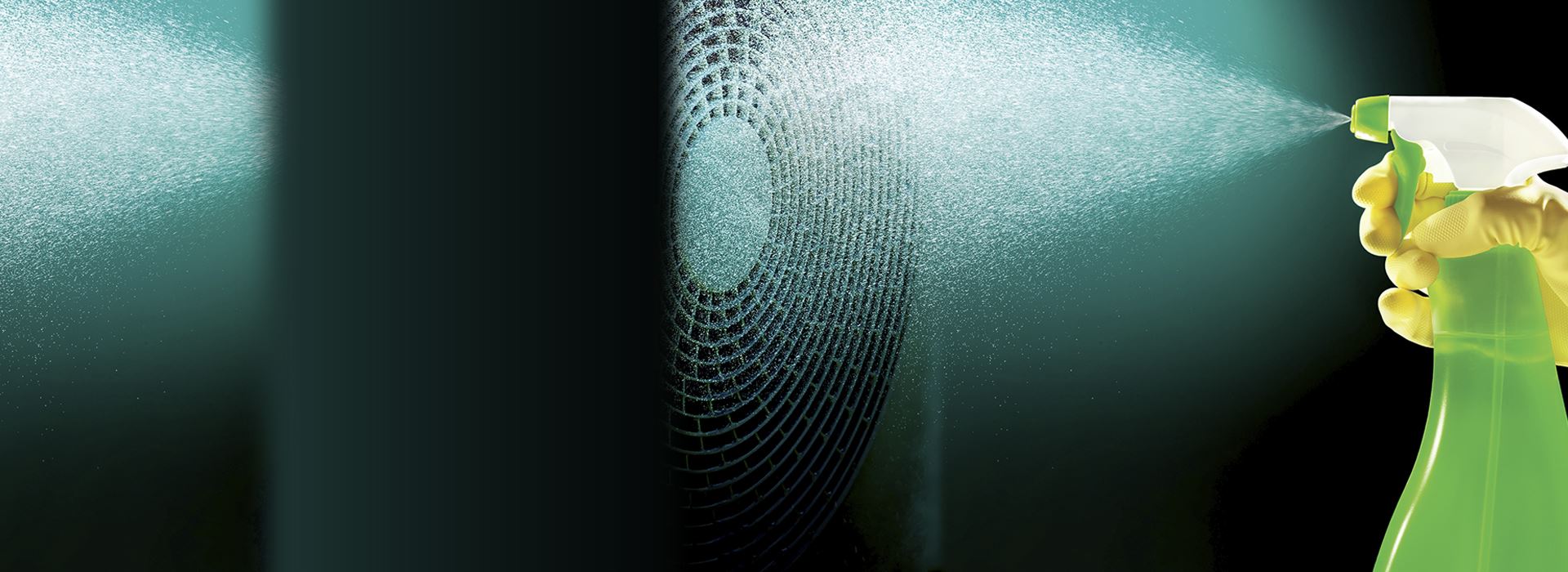

Cleaning disinfectants and antimicrobials can play a significant role in indoor air quality (IAQ) improvement. Providing IAQ solutions is critical for the HVAC&R industry. One area of increasing interest is cleaning, sanitizing and disinfecting the hard surfaces of HVAC&R components to maintain a high level of IAQ. The first line of defense is to clean intake grilles and air registers and to change air filters on the regular schedule recommended by the system manufacturer. However, dust, dirt, grime and allergens will still build up in the system. That is where cleaners and antimicrobials can be used effectively. This article provides a foundation for understanding the differences between cleaners, biostats, sanitizers and disinfectants and the regulatory requirements specific to HVAC&R equipment and application methods. It also covers the differences between active and inert ingredients in EPA-regulated products. Condenser and evaporator coil cleaning are also reviewed, followed by application methods and a discussion on efficacy.

Cleaners can be water or solvent-based, or a combination such as an emulsion. Using only water is very safe, but not very effective. Solvents can be dangerous due to flammability, volatile organic compounds (VOCs), etc., and may not be compatible with many surfaces such as plastics, thermal and electrical insulation, paint and labels. Surfactants play a key role in cleaners. These “surface active agents” provide a number of benefits when used with water, solvents and combinations thereof. An important function of a surfactant is to lower the surface tension of a solution. This allows the liquid to more easily penetrate the interface between two solids, such as between the surface to be cleaned and a dirt/grime particle, which achieves a more effective cleaning.

Read the Full Article

ASHRAE Members have free access to the full-text PDF of this article as well as the complete ASHRAE Journal archives back to 1997 in the Free Member Access Area.

Non-members can purchase features from the ASHRAE Bookstore. Or, Join ASHRAE!

Return to Featured Article Excerpts

Return to ASHRAE Journal Featured Article Excerpts