©2022 This excerpt taken from the article of the same name which appeared in ASHRAE Journal, vol. 64, no. 3, March 2022.

About the Authors

Shiro Tsukami, P.E.jp, is the engineering director of the Building Services Design Division, Kitaro Mizuide, Ph.D., P.E.jp, is the executive officer and principal of the Building Services Design Division, and Hirotaka Kubo, P.E.jp, is the mechanical engineering of the Building Services Design Division at NIKKEN SEKKEI LTD.

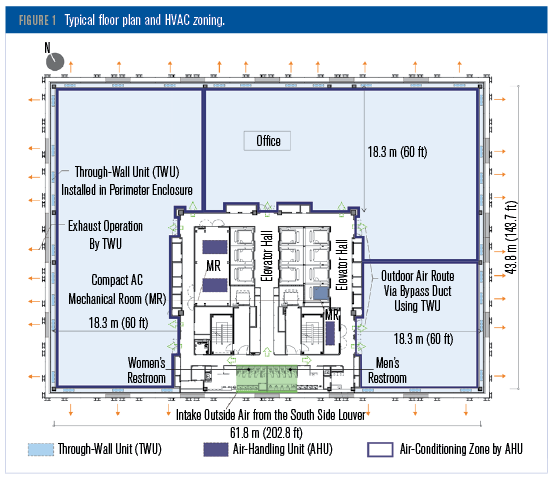

DaiyaGate Ikebukuro, the first tall office building in Tokyo, Japan, connects to Ikebukuro Station, the third-busiest railway station in the world. Tokyo has more than a 70% chance of experiencing an earthquake with a magnitude of 7 or greater in the next 30 years, and the high-rise was designed with resiliency in mind. It features a new combination HVAC system of central air-handling unit (AHU) and perimeter through-wall units (TWU), using exhaust heat recovery in the TWU for a high-rise building to achieve independent cooling/heating plus ventilation, along with comfort and good air quality (Figure 1). The project received the 2022 ASHRAE Award of Engineering Excellence.

This system, by successful integrative design, achieved a healthy building that combines energy conservation, resilience and indoor environmental comfort, considering the health of the occupants and operational management. The TWUs installed in the perimeter enclosure are harmonized with the outer-braced structure, allowing good daylighting and views and a high effective floor area ratio.

Energy Efficiency

The actual source energy use intensity (EUI) for the entire building was reduced by about 58% compared to the Japanese energy-saving standard and by about 44% compared to the ASHRAE Standard 90.1-2007. The annual primary energy consumption of the building was 1,043 MJ/m2·yr (92 kBtu/ft2·yr), which is less than the average value of 1,814 MJ/m2·yr (160 kBtu/ft2·yr) for office buildings in Tokyo. Japan. Key data and their contribution to energy savings are shown here:

The south core plan arrangement, external walkways and bracing, solar-tracking (automatically controlled) blinds and low-e glass dramatically improve the exterior skin performance. The outer skin performance resulted in the greatest energy load reduction (28% reduction from the standard value).

The heat source system for the AHUs consists of air-cooled chillers and gas burning absorption chillers, considering the functionality and redundancy of the heat source system operation. A heat storage water tank has been used to level the load and reduce peak demand. The peak power demand of the building is 38 W/m2 (3.5 W/ft2), which is very low, because the chilled water storage tank assists cooling demand during summer peak hours (26% peak demand reduction, compared to the case without the tank).

The heat source system was verified for optimal operation patterns using a life-cycle energy management (LCEM) simulation tool. The tool, developed in Japan, can calculate energy consumption in partial-load operation by reflecting the operating characteristics of heat source equipment, such as partial load and outdoor temperature characteristics at different times of the day. It was estimated by this simulation that the preferential operation of the electric heat source during the daytime and operation of heat dissipation from the heat storage tank during off-peak hours was very efficient and enhanced the system COP per day by about 2%. Therefore, these results are reflected in the actual operation.

The TWU’s exhausting indoor air operation improved the efficiency by approximately 30% compared to the outdoor air circulation operation of a standard unit.

Compared to energy consumption data of commercial buildings, the actual primary energy for the HVAC&R systems showed an annual energy-savings effect of about 46%. In summer, the reduction is about 55%, and it’s about 65% during the intermediate seasons. In the winter, however, gas consumption for fresh air load treatment is large, and the reduction rate is about 30%.

Read the Full Article

ASHRAE Members have free access to the full-text PDF of this article as well as the complete ASHRAE Journal archives back to 1997 in the Free Member Access Area.

Non-members can purchase features from the ASHRAE Bookstore. Or, Join ASHRAE!

Return to Featured Article Excerpts

Return to ASHRAE Journal Featured Article Excerpts