©2021 This excerpt taken from the article of the same name which appeared in ASHRAE Journal, vol. 63, no. 9, September 2021.

About the Authors

Tomoaki Ushio, P.E., is a design engineer at NIKKEN SEKKEI Ltd. in Japan. Harunori Yoshida, Ph.D., is a chairman of Building Commissioning Association, NPO Japan and a professor emeritus at Kyoto University. Shigemi Mori is a construction engineer at Takasago Thermal Engineering Co., Ltd. in Japan.

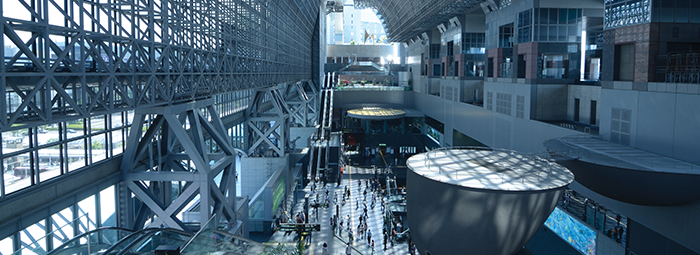

The Kyoto Station Building is the symbolic gateway to Kyoto in Japan. But when the Japanese government certified Kyoto as an environmental model city in 2009, Kyoto Station was the city’s most energy-consuming single building. The owner decided to initiate a radical energy retrofit, which included applying a life-cycle commissioning process. Results of the project include reducing the building’s heating and cooling plant energy by nearly 60%.

Energy Efficiency

The analysis of energy consumption of the original central plant system in the investigation phase showed that the cooling load was more significant than the heating load; the chilled water was mainly produced by a steam-driven absorption chiller, which has low efficiency compared to an electric heat pump system. The chiller plant size was also so large that the chillers worked at low load. The steam system had low efficiency and a lot of heat loss. For example, 27% of the heat generated by the steam boilers was lost in the distribution piping.

One reason a steam system was adopted for the original project was the limitation of power transmission capacity. The power company set its peak power demand for each region based on the floor-area ratio, as allowed by urban regulations. When the original station design began in 1990, these rules were relaxed and the building was allowed to double in height and area. To succeed with a radical energy retrofit of the building, the building owner decided to introduce the commissioning process, which included a large energy savings target. To fulfill this, the design team made three countermeasures, which comprise reducing the chilled water capacity, changing to an all-electric system using maximum efficiency chillers and adopting a cogeneration system to reduce peak power demand through commissioning meetings.

In this project, the annual trend of chilled water demand was carefully researched during the investigation phase of commissioning prior to design phases. It was determined that chilled water system capacity, including one backup chiller, could be reduced by 20%, using actual energy consumption data for the past three years and energy-savings calculations that reduced outdoor air volume, while satisfying sufficient air volume per person. The other advantages of this approach are creating replacement space and decreasing initial cost.

Based on the reduced chilled water capacity, a variety of central heating and cooling systems were studied by the design team to uncover optimum and significant energy reductions. These systems included a gas-fired steam system, which is the same as the original system; an all-electric heat pump system; mixed systems using both and more. Thirteen variations of central heating and cooling systems were compared for initial cost, energy cost and annual cost based on their initial cost, primary energy consumption and electrical peak load.

An all-electric heat pump system using variable-speed centrifugal chillers and air-source heat pumps was the most efficient. But this system was expensive due to changing the steam system to a hot water system. So it was decided to postpone replacing part of the steam system and to replace this in the near future. A gas-engine-driven cogeneration system was added for the reduction of peak power demand and energy cost. Peak power demand is now almost the same as the original peak demand. This modified system was selected.

Read the Full Article

ASHRAE Members have free access to the full-text PDF of this article as well as the complete ASHRAE Journal archives back to 1997 in the Free Member Access Area.

Non-members can purchase features from the ASHRAE Bookstore. Or, Join ASHRAE!

Return to Featured Article Excerpts

Return to ASHRAE Journal Featured Article Excerpts