Wilde Lake Middle School

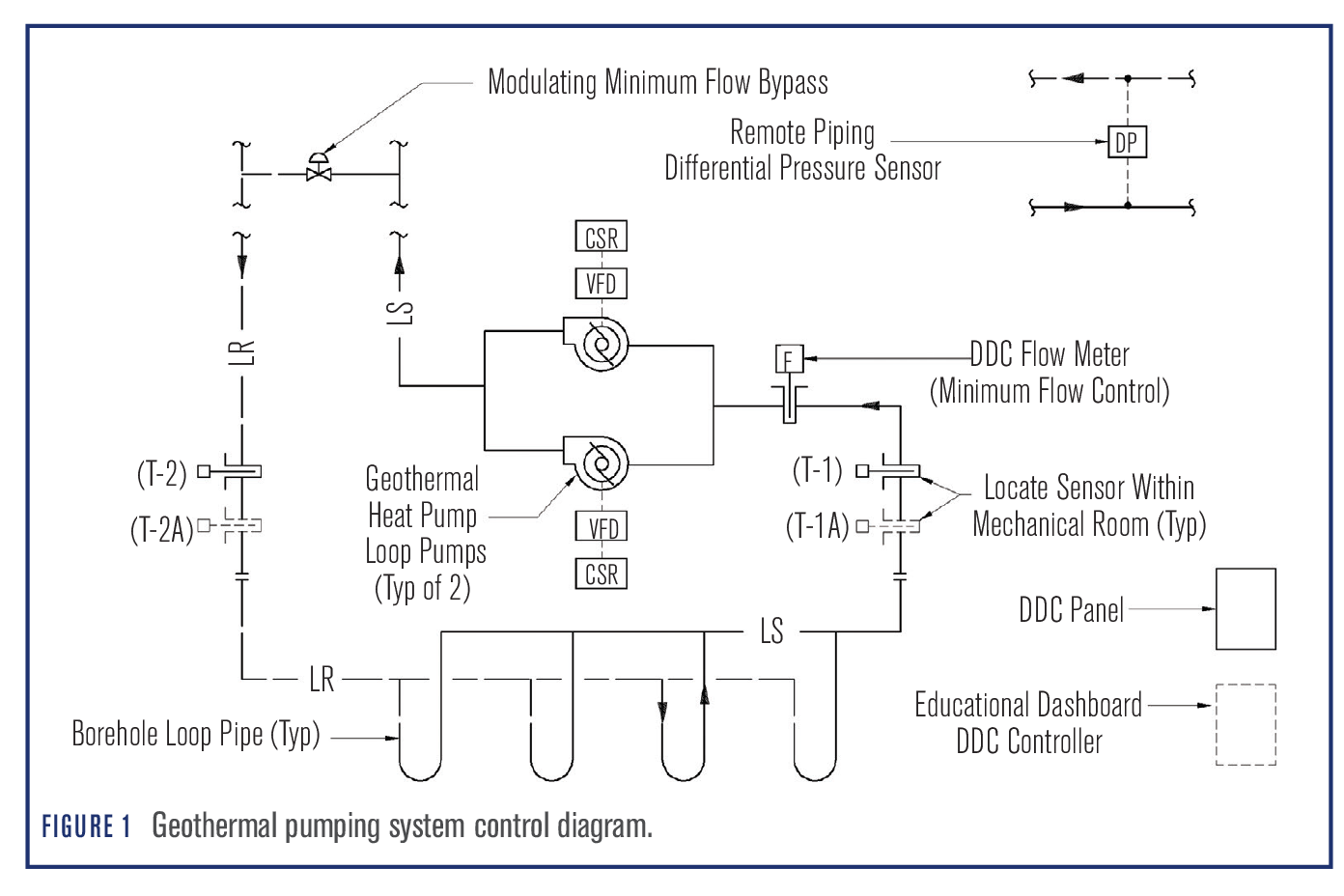

This 2019 ASHRAE technology award winner shows how standard technologies when designed and coordinated properly can provide a high performing outcome. The use of water source heat pump with a geothermal well system provided for a net zero outcome that is utilized within the school district today as a template for future schools.

Techniques utilizing the need for “Team Process”

- Prior to construction beginning, the contractors built a mockup of the typical heat pump assembly including the unit, piping, sheet metal, electrical and general trades. Since the classroom assembly was typical throughout the school, this mockup allowed for all trades to work through any coordination issues not seen in the design process, discuss those issues with the designers and owner and allow for a more efficient installation at the time of construction.

- PV was integrated into the design and implemented as part of the project. The installation is located on the roof of the building and provides renewable energy for the building and feeds excess power into the grid. This provides for a cost-effective operational expense with additional resiliency for the owner. This coordination of designers, installers, and operators allows for an optimum outcome.

|

|

Source: 2019 ASHRAE Technology Awards: School Design Exceeds Net Zero Energy Goals, ASHRAE Journal, vol. 61, no.5, May 2019

|

|

| Source: 2019 ASHRAE Technology Awards: School Design Exceeds Net Zero Energy Goals, ASHRAE Journal, vol. 61, no.5, May 2019 Credit: Coyle Studios LLC. |

Audain Art Museum

This 2020 ASHRAE technology award winner shows how continuing need for resiliency must be coordinated amongst all stakeholders during design through operation of the building. Simple strategies planned properly will provide the needed outcome.

Techniques utilizing the need for “Team Process”

Due to the location of the building and potential flooding great care was placed into the elevation of the building and supporting system design. Since the building must maintain proper temperature and humidity control year-round due to the artwork inside the structure resiliency was paramount.

- To avoid potential flooding, the building was elevated to withstand a 2,500-year event. Features were design to allow for water to pass under and around the structure in the event of a flash flood in such a way not to impact structure integrity or operational use.

- Envelope was designed with R-55 roof, R-23 walls, and triple pane glass. This provided challenges for the HVAC system due to the potential low loads and mandates coordination the control system be capable and reactive. Additionally, the designers accounted for the need to the BAS to user friendly such that monitoring and adjustments can be made as necessary by the owner.

- Redundant systems including Chillers, Boilers, and AHUs provide for the resiliency needed

- Simple load shedding strategies were also designed and implemented to allow the building to account for issues with the mechanical system or potential utility issues. The BAS handles the implementation of the strategy but the owners’ staff were also trained as well for coordination of future needs.

Ochsner Grove Medical Complex

This is a 250,000 ft2 ambulatory care clinic is between a new residential development and the busiest highway in Baton Rouge. Site logistics and schedule were the two largest constraints in bringing the project forward.

Techniques utilizing the need for “Team Process”

- The project was implemented utilizing a design-build contractor with full integration of design files and fabrication techniques. This allowed for a single coordinated drawing process. The piping design allowed for the piping modules to be completed offsite to minimize field labor. The installation of equipment and piping inside the plant was completed in less than four weeks.

Additionally, the plant was operational ahead of schedule to allow for temporary cooling of building for finishes.

- 3D As Built documents are available and utilized by the building operators for maintenance usage and redundancy protocols. This enables the operators to have information at their fingertips when needed for trouble shooting. Additionally, this facility acts as a training location on best practices for other operations teams building SOPs for emergency procedures.